Special Fuels Demand Special Treatment

Cogeneration Releases the Value Stored in Waste Gases

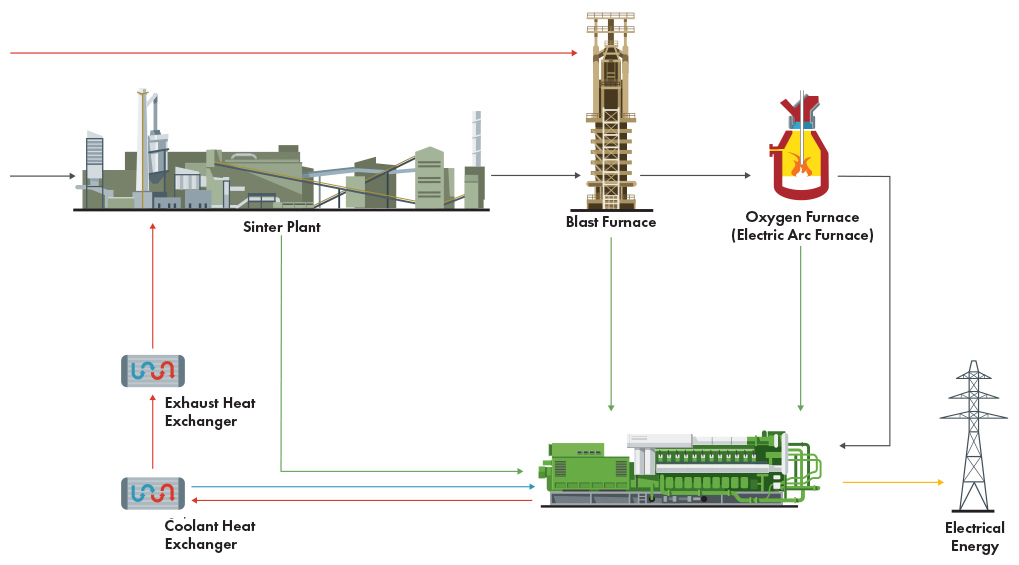

Special gases are often produced by industry as part of essential processes and are seen as waste. The steel industry produces blast furnace gas, coke oven gas, and converter gas. Other special gases include syngas from waste and woodgas from timber. The combustible portion of these special gases includes a mix of hydrogen (H2) and carbon monoxide (CO). Enerflex has state-of-the-art systems to extract value from special gases in the form of electricity and heat.

Putting Greenhouse Gases Back to Work

Gas engines, using syngas, leverage a combined heat and power (CHP) configuration to maximize efficiencies. Furnace gases can also be recycled this way, reducing high CO2 emissions from energy-rich industrial processes. Instead of trying to dispose of problem greenhouse gases, customers can use Enerflex’s solutions to redirect valuable energy into their production lines.

With Enerflex as part of the mix, industrial and municipal customers can develop an independent and predictable power supply from their own waste resources, whether syngas or furnace gas. The electrical efficiency of the gas-driven solution is far higher than comparable alternatives, such as steam or gas turbines. Special gas systems are best suited for output ranges between a few hundred kW to 30 MW, and where gas pressure is low. Enerflex units are simple and rugged, with long maintenance intervals.

Special Gas to Power. Enerflex Delivers.

Enerflex in Action

- Westbury, Quebec, Canada

422 kW Power Generation Solution from Wood Gas

A clean energy company wanted to generate power from wood gas produced through the gasification of recovered telephone poles. The Enerflex solution was to refurbish and retrofit a used Jenbacher J312 gas engine. The 480V unit produces 422 kW at 1,800 RPM in island mode.

Outcome

The Enerflex service and retrofit teams were able to provide a fast and cost-effective solution by re-using an older Jenbacher J312 containerized unit from the USA. The project demonstrates that wood gas can be used to generate electricity economically, even in a challenging environment.