Equipment / Electric Power

Oil and Gas

Turnkey Power for Oil and Gas Sites

Enerflex handles engineering, fabrication, installation and operation to deliver fully integrated power solutions for oil and gas sites—so you can focus on core operations.

Flare Gas to Power

Enerflex has developed comprehensive solutions to convert associated petroleum gas, or field gas, to power at high efficiencies using reciprocating natural gas engines. Our solutions are able to operate in remote locations, throughout extreme temperatures, and using waste streams with high levels of impurity.

The Enerflex Edge

Wide-Ranging Abilities

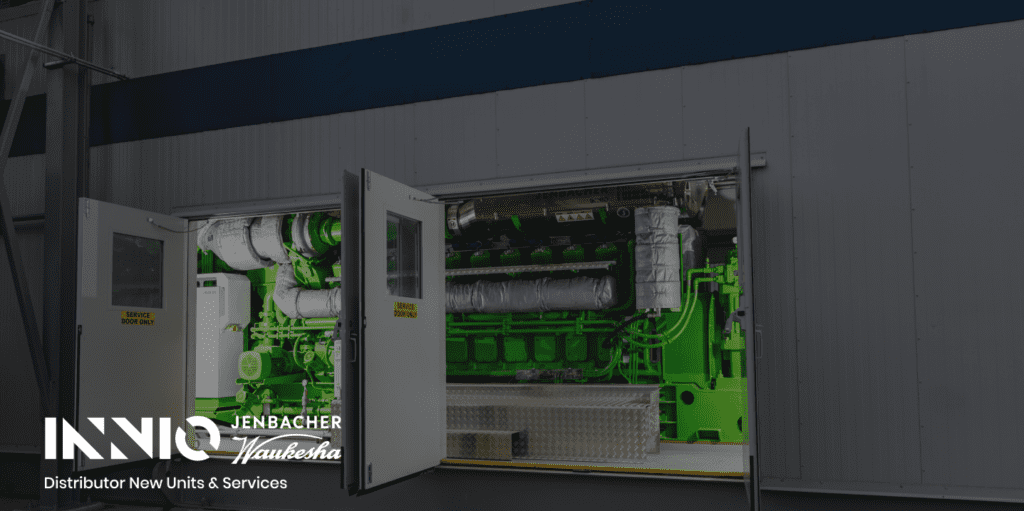

Our experience with multiple OEMs, including Jenbacher, Waukesha, Caterpillar, and MAN, means we have access to the best engines to fit your gas composition.

Built on Oil and Gas Expertise

With over four decades of oil and gas experience, we understand your challenges and deliver solutions that align with the industry’s demands, ensuring efficient power performance every time.

End-to-End Power Solutions

Our power generation and gas processing capabilities will seamlessly integrate into your facilities, providing dependable power tailored to your operational needs.

Our Partners

Enerflex is the Jenbacher Distributor and Service Provider for Canada and also provides Jenbacher products and lifecycle solutions across most USA states. The Company is also a global Platinum Power Packager for Waukesha engines and parts.

Comprehensive Solutions for Oil and Gas Power Needs

Versatile Power Applications

- Drill rigs

- Artificial lifts

- Pump jacks

- Compressor stations

- Gas processing plants

- Work camps

Adaptable to Varying Fuel Quality

- High-BTU field gas

- HD-5 propane

- Ethane

- Able to replace diesel rigs

Customized Engine Configurations

- High altitude

- Rich-burn

- Lean-burn

- Fuel flexibility

Case Study

Nine Gensets for Continuous Duty and Remote Oil and Gas Processing

Challenge:

In Africa, we faced the challenge of delivering reliable power generation in harsh desert conditions, marked by extreme temperature fluctuations and heavy air contamination from sand. The remote location added logistical and maintenance complexities.

Solution:

We supplied nine modular gensets, including five PWC1000S-HA and four PWC1200S-HA Waukesha VHP engines, fueled by onsite field gas. The modular design allowed for phased installation across three sites.

Outcome:

Collaborating with our teammates in the Middle East, the setup achieved stable operations despite high temperatures and air contamination, ensuring reliable, continuous power in this remote desert region.

Discover Related Products and Services

Electrification

Services