Equipment / Processing

Cryogenic / Deep Cut

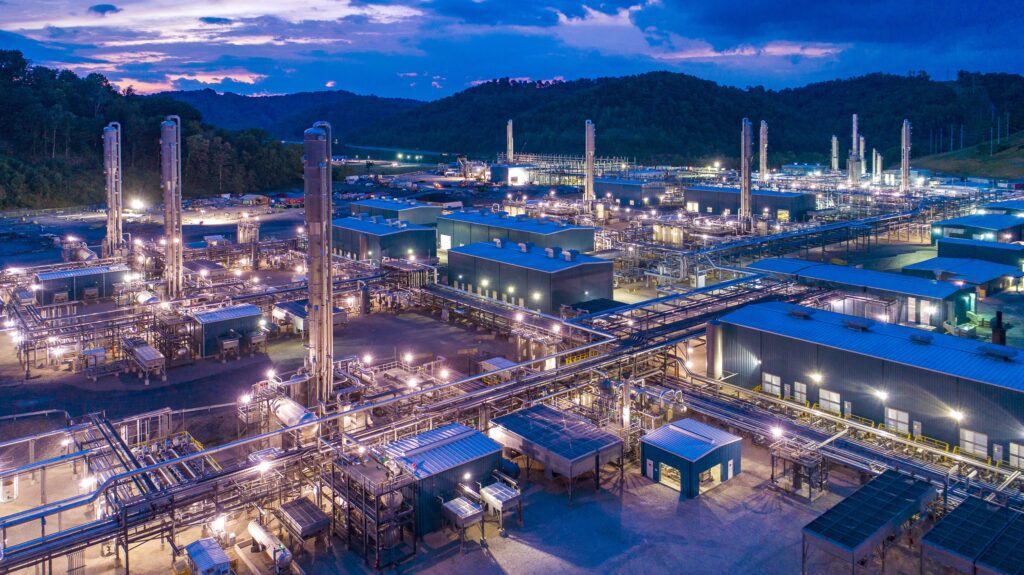

Trusted Cryogenic Solutions for 40+ Years

Cryogenic processing cools liquids-rich natural gas to sub-zero temperatures to extract liquids, increasing revenue for natural gas producers. Our modular plants provide industry-leading performance and reliability.

The Enerflex Edge

Flexibility in Design and Operation

Our plants are designed for flexibility, adapting to various site needs and process configurations. Fully digitized controls provide smooth integration, ensuring efficient, reliable operations.

Maximized Recovery with Advanced Turboexpanders

Our cryo plants use cutting-edge turboexpanders to achieve deep ethane and propane recoveries of up to 99%, even at temperatures as low as -112°C, ensuring producers maximize revenue.

Customized to Your Needs

Our cryogenic systems are tailored to your specific operational requirements. We maximize recovery, optimize throughput, and handle complex gas compositions, delivering solutions designed for you.

Solutions

Our designs for cryogenic plants are modular and flexible, offering a variety of options.

- Molecular sieve dehydration

- Turboexpanders that cool the gas while generating mechanical energy to drive the booster compressor, which partially recompresses the residue gas stream

- Optimized thermal integration, resulting in reduced power consumption and CAPEX

- Mechanical refrigeration unit add-ons for supplemental cooling of highly liquids-rich gas

- Additional options such as inlet and residue compression, mercury removal, a hot oil system, pipeline pumps, amine treating, and TEG dehydration

Case Study

Custom 300 MMSCFD Multi-Process Cryogenic Plants

Challenge:

Enerflex was tasked with engineering, designing, manufacturing, and commissioning two custom built, multi-process 300 MMSCFD cryogenic plants. The client partner needed flexibility for various operating modes—GSP, SCORE, and SRC—along with deep propane recovery, and minimal compression power to reduce long-term operating costs.

Solution:

We provided a stick-built, semi-modular design with two cryogenic NGL recovery processing trains. These trains featured amine units, molecular sieve dehydration, refrigeration compressors, and centrifugal residue compressors. A common NGL system enabled the flow of product to a Y-grade pipeline for fractionation.

Outcome:

The project, located in DJ Basin, Colorado, USA, was completed on time, within budget, and with zero safety incidents. Enerflex’s custom design enabled high propane recovery and provided flexibility for future ethane markets. The plant has exceeded design expectations, and led to additional work across all four project sites.

Case Study

200 MMSCFD Integrated Turnkey Cryogenic Plant

Challenge:

We were asked to deliver a 200 MMSCFD cryo plant integrated with a 10,000 BBL/D stabilizer, more than doubling the customer’s processing capacity. The clientt, based in Powder River Basin, Wyoming, required a custom solution that prioritized propane recovery, with flexibility for future ethane expansion.

Solution:

We designed a plant with a two-tower stabilizer to minimize compression. Key components included molecular sieve beds, a 5,000 HP residue gas compressor, and onsite storage for NGL and condensate. The design focused on 94% propane recovery, optimizing energy use and eliminating the need for a refrigeration system.

Outcome:

The project was completed on time, with Enerflex managing the entire balance of plant design, construction, and commissioning. The plant’s flexibility maximized propane and condensate value, and Enerflex’s site team efficiently managed over 400 workers, delivering the project within budget and without incident.

Discover More About Our Products and Services

Build-Own-Operate-Maintain Solutions

Field Services