The Cleanest Fossil Fuel is On the Move

LNG has All the Advantages of Natural Gas Plus Safe Transportation and Storage

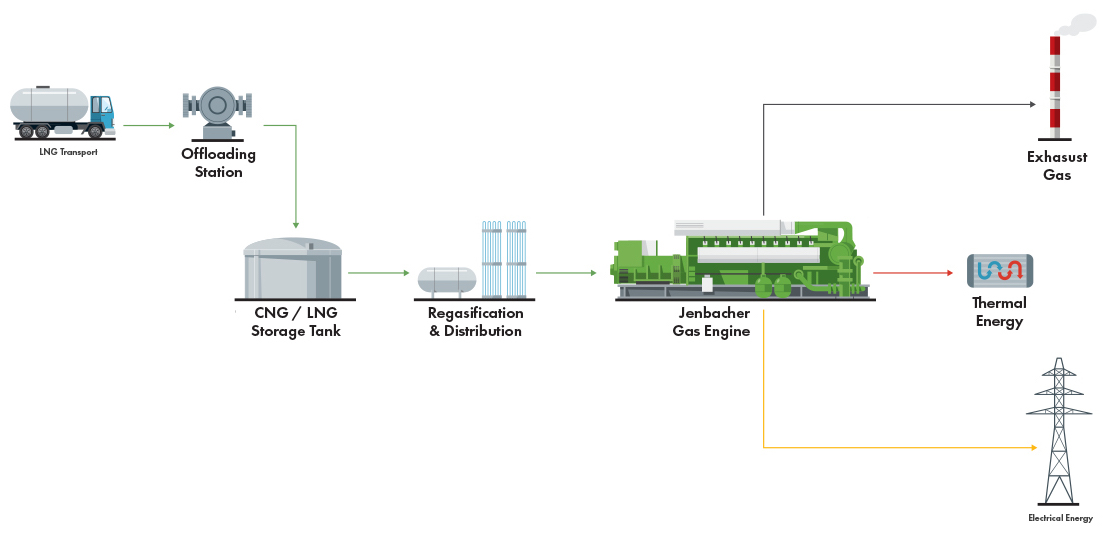

Natural gas power generation is known to be the cleanest fossil fuel-based power method. When remote communities and mines do not have access to a pipeline for natural gas supply, the alternative is liquefied natural gas (LNG)-to-power.

Natural gas is liquefied at -170°C (-274°F) so that it is easily transportable by truck, train, and ship to remote locations. Enerflex systems include the reception and storage of LNG followed by regasification systems to return liquid gas to its gaseous state. Whether you are in a remote community, mine site, or industry, you should investigate how LNG cogeneration can help you reduce your operating costs and lower your environmental footprint.

Gas-to-Power is a Global Trend

The entire power industry needs new business models to effectively handle the high penetration levels of non-dispatchable renewables in modern power grids, and the strong demand for flexible, highly efficient, and clean dispatchable power solutions. These also require a strong focus on CO2 reduction and optimizing electricity costs.

Exploring a variety of innovative technologies and combining different sources of energy can help lower expenditures by ensuring the smartest energy mix. A key element in our efforts to achieve a carbon-neutral future is LNG, which generates considerably less CO2, sulfur dioxide, nitrogen oxide, and particle emissions than any other fossil fuel. Gas-to-power has become a rapidly growing global trend, with LNG available for power generation practically anywhere with access to the sea or a receiving LNG terminal. Independence from existing gas infrastructure and pipelines, combined with cost-effective operations, are essential to the future viability of this technology.

Enerflex in Action

- Whitehorse, Yukon, Canada

8.8 MW Cogeneration Hydro / LNG Power Plant

Enerflex provided our customer Yukon Energy with a complete LNG fueled power generation system. The project objective was to replace aging diesel gensets with a new facility with higher efficiency and lower carbon footprint. The 13.2MW LNG power facility provided by Enerflex included three Jenbacher JMC624 twin-stage turbocharger gensets. These state-of-the-art modular gensets are ultra-low noise modules made for harsh arctic conditions. The project also included a complete switchgear-ehouse, fluid module, heat recovery for LNG regasification, and a master scada for full micro-grid integration.

Outcome

Enerflex engineered, supplied, installed, and commissioned a turnkey solution for the client and is today providing full life cycle maintenance of the plant. The Yukon grid can count on this high-efficiency plant to keep the lights on throughout the year, especially during the cold winter months.