Equipment

Electric Power

Powering Your Operations Anywhere in the World

We deliver electric power solutions from 20 kW to 100 MW, offering flexible configurations, fuel options and high-efficiency systems for any industry, anywhere.

+90%

Overall plant efficiencies achieved with cogeneration or CHP systems

40+

Years’ experience in power generation, bringing proven solutions to diverse industries

24/7

Support, no matter how remote the location

The Enerflex Edge

Scalable, Reliable Power Anywhere

From single-engine setups to full turnkey multi-engine plants, our solutions deliver consistent power in both remote areas and urban centers, minimizing costs and maximizing uptime.

Cost-Effective, Modular Peak Shaving

Modular designs simplify installation and support peak shaving, reducing grid reliance and energy costs. Systems adapt quickly to site needs while enabling asset redeployment.

Versatile, Low-Emission Designs

Our rich, lean-burn configurations run on multiple fuel types, delivering high efficiency, reduced emissions, and CO₂ capture for sustainable operations.

Comprehensive Power Solutions

Gas-Driven Engine Capabilities

- Natural gas

- Biogas

- Greenhouse

- Sewage gas

- Landfill gas

- Syngas

- Solution gas

- Flare gas

- Propane

Full Electric Power Solutions

- Island-mode prime power configurations

- Fast-response peak shaving

- Cogeneration and trigeneration (CHP)

- Temporary, standby and backup power options

- Remote off-grid island operation

- Complete turnkey solutions, including field construction

- Equipment-only supply or full engineering and design services

- Renewable firming

- Special gas handling

Our Partners

Enerflex is the Jenbacher Distributor and Service Provider for Canada and also provides Jenbacher products and lifecycle solutions across most USA states. The Company is also a global Platinum Power Packager for Waukesha engines and parts.

Jenbacher products by the INNIO Group

Since the early 1990s, Jenbacher technology has powered North America with over 1,000 engines producing 1.7 GW of electricity. These cutting-edge solutions deliver reliable, efficient energy for both on-grid and off-grid applications—wherever it’s needed.

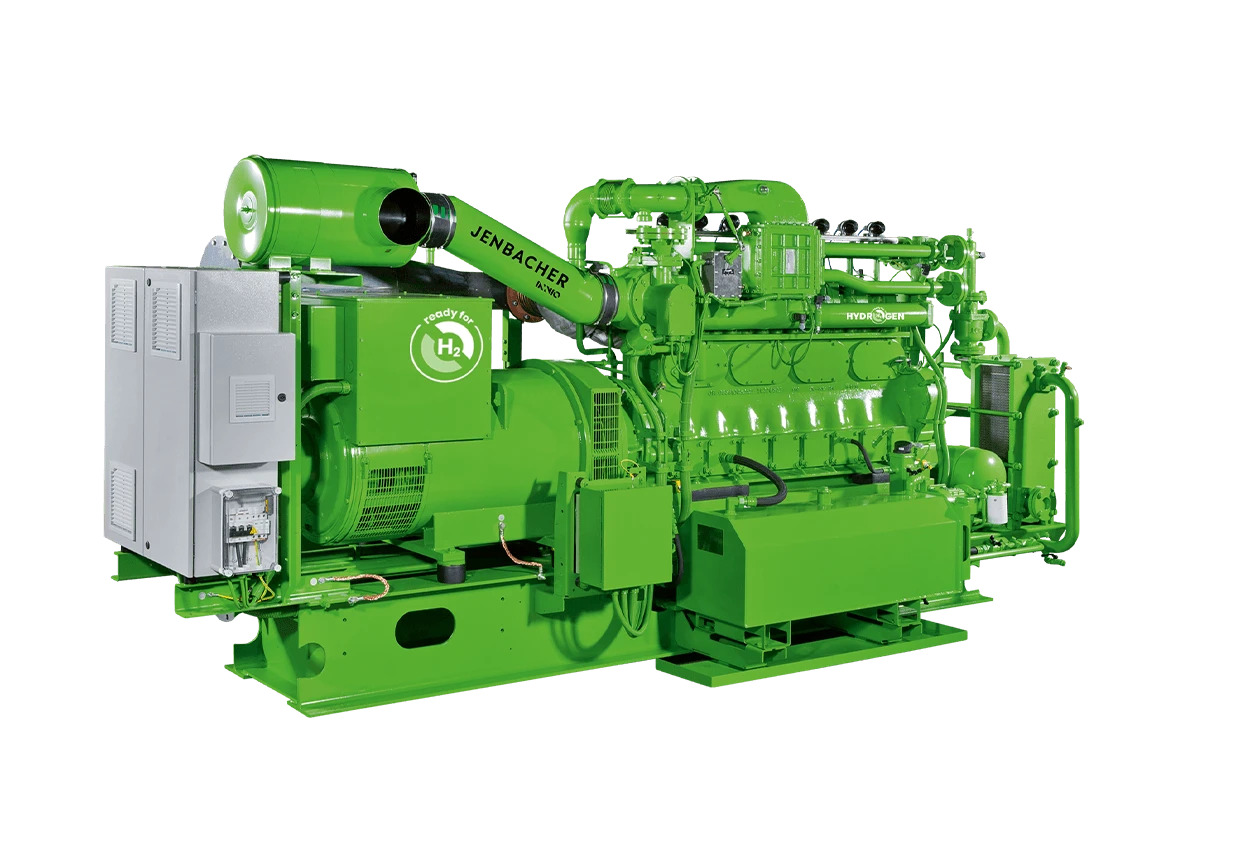

The Jenbacher Type 2 Engine

Ideal for small to mid-scale needs, this engine delivers 335 kW of efficient power with unmatched durability and fuel flexibility.

The Jenbacher Type 3 Engine

This engine delivers 635-1,062 kW of reliable power with low fuel consumption, long service intervals and a design built for operational efficiency.

The Jenbacher Type 4 Engine

Delivering 851–1,429 kW of power with high power density, this engine offers advanced efficiency and reliability—perfect for mid-scale operations.

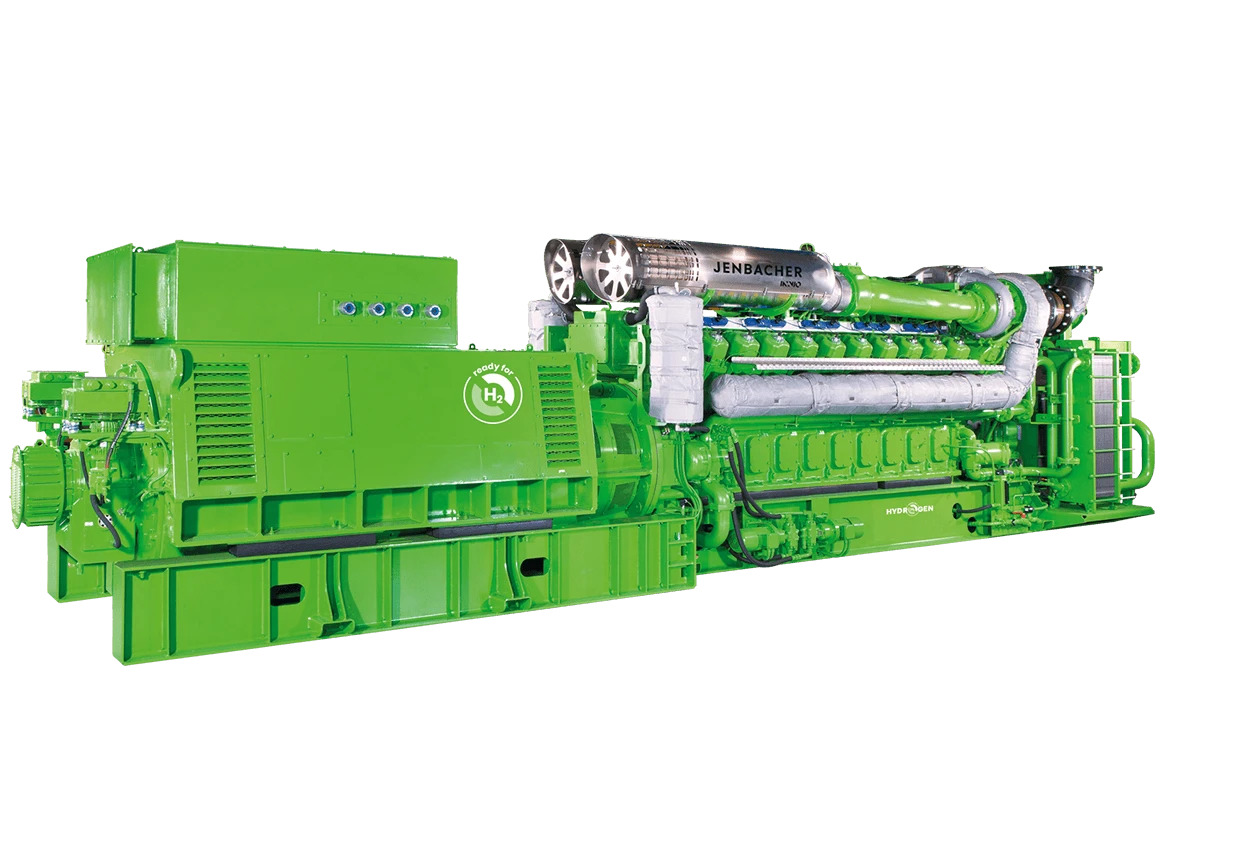

The Jenbacher Type 6 Engine

Best suited for large-scale energy needs, this engine brings 1,798–4,481 kW with advanced efficiency, low emissions and reliable heat recovery capabilities.

Case Study

9 MW Cogeneration Plant — Wastewater Treatment Facility

Challenge:

A wastewater treatment plant in Slave Lake, Alberta, Canada, needed a solution to capture and convert biogas into a renewable energy source. This required modifying the existing system to clean the biogas of excess water and H₂S for safe energy conversion.

Solution:

We designed and installed a turnkey cogeneration plant, featuring three Jenbacher J620 engines that deliver over 9 MW of electrical output. The modified system captures and cleans biogas, converting methane into power and thermal energy.

Outcome:

The upgraded treatment facility now generates clean biogas, producing renewable electricity and heat, which offsets a substantial portion of utility costs and significantly reduces the plant’s environmental impact, turning a waste stream into an energy source.

Case Study

16,800 kW Mobile Power Generation — Utilities

Challenge:

A Canadian utilities company needed a compact, mobile power generation system that could handle extreme temperatures, from -50°C (-58°F) in winter to 40°C (104°F) in summer, while remaining versatile for various locations.

Solution:

Enerflex provided twelve PJC1400S units featuring JGS 420 Jenbacher engines, each generating 1,400 kW at 4.16 kV. The total system delivers 16,800 kW with utility-grade, medium-voltage switchgear. The package includes Stamford generators, Sutton Stromart radiators, and DIA.NE-Woodward control systems, all built to Canadian electrical, gas, and utility codes.

Outcome:

The tailored mobile solution met the client’s specifications, offering seamless transportability and flexible deployment across sectors, including oil and gas, utility firming, greenhouses, and emergency backup.

Services

Our comprehensive services include field support, retrofits and long-term maintenance agreements. We ensure operational reliability, boost asset lifespan and enhance productivity worldwide—wherever you operate.